Understanding Ventilation Needs in a Large Greenhouse

The Critical Role of Ventilation in Large Greenhouse Climate Control

Good airflow keeps things from getting too hot or humid inside big greenhouses, which helps prevent those little pockets of bad weather that can really hurt plants growing there. According to research published last year in AgriTech Frontiers, greenhouses that had better air circulation experienced around 40% fewer problems with fungus and saw their crops grow much more evenly across the board. Another important thing is making sure carbon dioxide spreads out properly so plants can photosynthesize well. When CO2 drops below about 200 parts per million, plant growth slows down dramatically, sometimes by as much as half according to a report from USDA on plant physiology back in 2023.

How Greenhouse Size Affects Airflow and Temperature Distribution

Larger structures face unique challenges:

| Greenhouse Size | Air Exchange Rate Needed | Temperature Differential* |

|---|---|---|

| <1,000 sq ft | 10–15 exchanges/hour | ±2°C |

| >10,000 sq ft | 20–30 exchanges/hour | ±5°C |

| Source: Controlled Environments Journal (2023) | ||

| The cubic air volume in large operations requires proportional increases in ventilation capacity. For example, a 100' x 200' greenhouse needs 43% more fan power than a 50' x 100' structure to maintain equivalent airflow. |

Key Environmental Factors: Temperature, Humidity, and CO₂ Management

Three interconnected elements dictate ventilation requirements:

- Temperature: Most crops require 18–27°C ranges, with <5°C variation across zones

- Humidity: Optimal 50–70% RH; levels >85% increase disease risk (USDA 2023 Pathogen Study)

- CO₂ Concentration: Maintain 800–1200 ppm during daylight hours

Automated systems combining humidity sensors and vent actuators reduce energy use by 22% compared to manual operation (2023 Greenhouse Tech Review). A Florida nursery achieved 25% higher rose production through coordinated ventilation managing these factors.

Passive Ventilation Strategies for Large Greenhouse Structures

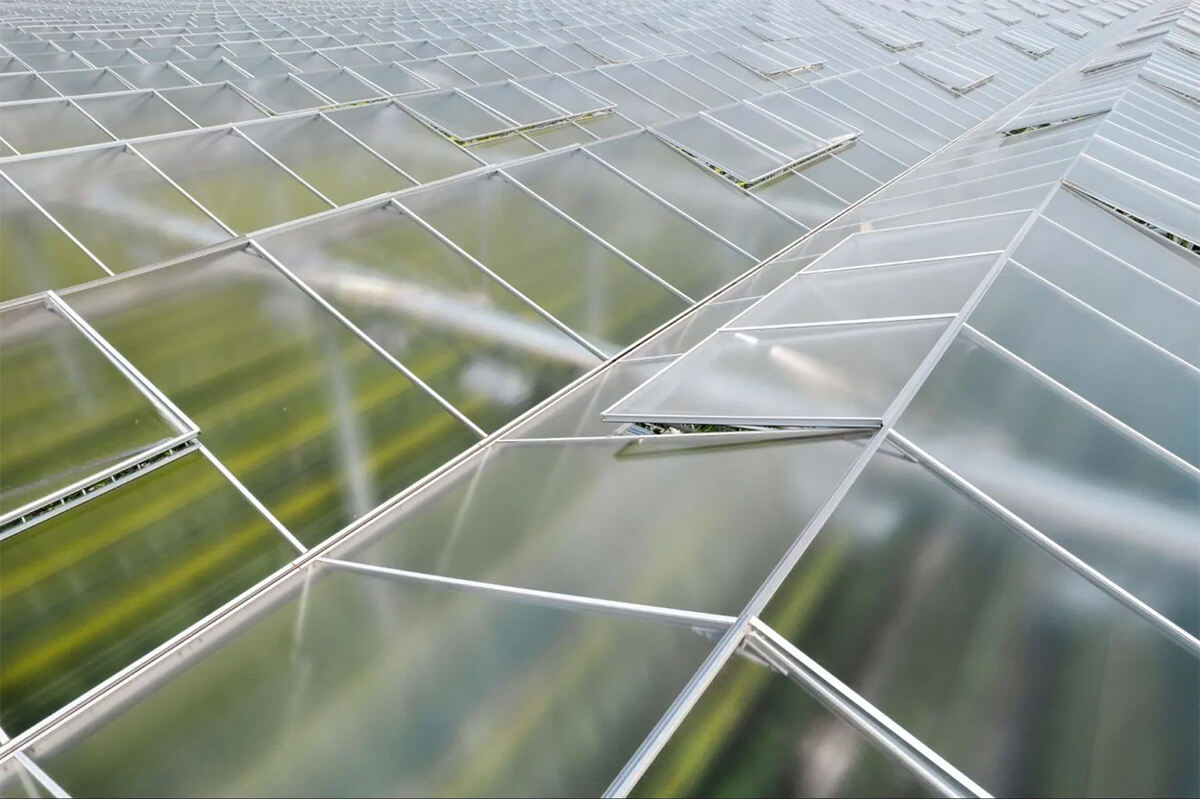

Roof Vents and Side Vents: Maximizing Natural Convection Currents

The passive ventilation system in big greenhouses works through clever placement of roof and side vents based on how hot air naturally moves upward. When the sun heats things up inside, those roof vents at the top let out the warm stuff. Most setups have about 1.5 to 2 cubic feet per minute of airflow per square foot space. Meanwhile, the side vents usually sit around 16 to 24 inches off the ground bringing in fresh cool air from outside. Some research done last year at the University of Agriculture showed something interesting too. Greenhouses that had both ridge vents plus automated side vents saw their hottest temperatures drop by roughly 14 degrees Fahrenheit when compared to older models with just fixed vents. This makes sense because these convection currents really kick in force when dealing with massive spaces over 10,000 square feet.

Roll-Up Sidewalls and Louvers for Scalable Cross-Ventilation

Flexible airflow management in big greenhouses often relies on roll-up walls and adjustable louvers. When temperatures climb in summer, rolling up around half the side walls lets hot air escape quickly. Meanwhile, those slatted panels set at about 15 to 30 degree angles help move air smoothly across the space without creating annoying turbulence. For commercial strawberry growers with fields over five acres, this setup keeps temperature differences between different parts of the greenhouse under three degrees Fahrenheit most of the time. That matters a lot because it stops damp spots from forming where fungus loves to grow, which can wreck entire crops if left unchecked.

Optimal Vent Sizing and Placement Relative to Large Greenhouse Capacity

According to the ASABE EP406.7 standards, ventilation areas need to cover around 20 to 25 percent of total floor space in big greenhouses. Greenhouses built north to south tend to get better airflow, about 23% faster actually, when they have those alternating vents on opposite sides facing the wind. Take a standard sized greenhouse measuring 50 by 200 feet as an example. These typically require roof vents covering somewhere between 65 and 80 linear feet. Pair that with 8 to 10 roll-up sidewall sections, each at least six feet tall, and growers can maintain air changes under three minutes throughout the day. This kind of rapid air exchange is critical for delicate plants such as lettuce varieties and various herbs that simply cannot tolerate stagnant warm air pockets.

Active Mechanical Ventilation Systems in Large Greenhouses

For large greenhouse operations exceeding 2,000 sq ft, active mechanical ventilation becomes essential to combat heat stratification and humidity buildup. These systems move 1.2–2 air volumes per minute—up to 240,000 CFM in commercial facilities—making them significantly more effective than passive methods in extreme climates.

Exhaust Fans and Intake Shutters: Core Components of Forced-Air Systems

High-capacity exhaust fans (36"–52" diameters) create negative pressure, drawing fresh air through intake shutters positioned on opposite walls. This pressurized airflow removes 85–90% of solar heat gain during peak hours when combined with cooling pads. Leading manufacturers recommend one fan per 1,500–2,000 sq ft for uniform air exchange in large greenhouse layouts.

Circulation Fans for Uniform Air Distribution and Microclimate Control

Horizontal airflow (HAF) fans spaced every 40–50 ft eliminate microclimates by maintaining 4–6 mph airspeeds at plant level. In a 2023 Rutgers University trial, this setup reduced fungal disease incidence by 70% in 5-acre tomato greenhouses by stabilizing humidity variance below 12%.

Sizing Fans and Calculating CFM Requirements for Large Greenhouse Spaces

| Greenhouse Size | Minimum CFM/Ft² | Total CFM @ 30'x100' | Energy Use (kW/Hr) |

|---|---|---|---|

| 3,000 sq ft | 8 | 24,000 | 4.5–6.2 |

| 10,000 sq ft | 12 | 120,000 | 18–24 |

| 25,000 sq ft | 15 | 375,000 | 45–62 |

Energy Efficiency Considerations and Operational Cost Trade-Offs

Variable frequency drives (VFDs) cut fan energy use by 35–40% in large greenhouse installations, with payback periods under 18 months in regions with $0.12/kWh rates. However, 24/7 operation during heat waves still accounts for 22–28% of total production costs in annual audits.

Hybrid Ventilation: Combining Passive and Active Methods for Optimal Control

Modern large greenhouse operations increasingly adopt hybrid ventilation to balance energy efficiency with precise climate management. By integrating passive roof vents and active fan systems, growers maintain optimal temperature and humidity levels while reducing reliance on energy-intensive mechanical solutions.

Design principles for adaptive hybrid ventilation in large greenhouses

Hybrid ventilation systems work best when they mix automated roof vents that cover around 15 to 25 percent of the roof space with horizontally positioned airflow fans placed at key spots. The system relies on temperature and humidity sensors to kick in mechanical ventilation only when natural air movement isn't enough to hit those target conditions. Studies from ScienceDirect back this up, showing these smart systems can cut down on fan operation time by roughly half in buildings over an acre in size. Before installing such a system, there are several important factors to consider during the setup process.

- Positioning intake vents on prevailing wind sides

- Installing circulation fans every 30–50 feet for air mixing

- Integrating motorized vents with CO₂ enrichment systems

Case Study: Energy-efficient hybrid system in a 10,000 sq ft commercial greenhouse

Tomato growers in Michigan have seen impressive results from their new approach combining traditional methods with modern tech. One farmer reported cutting energy costs by almost 30% after installing a mix of 48 automatic roof vents along with variable speed exhaust fans throughout his greenhouse complex. What really stands out is how well this works during those tricky shoulder seasons when temperatures fluctuate daily. For most of the day in spring and autumn, the natural airflow kept things at just the right temperature range, staying within three degrees Fahrenheit of what was needed around four out of five times during daylight hours. Climate specialists studying these systems agree that switching to this kind of setup typically cuts down on the need for expensive mechanical cooling by somewhere between 20 to 40 percent compared to greenhouses relying solely on forced air systems in comparable regions across the country.

Balancing automation with natural airflow to reduce energy use

Advanced controllers now use machine learning to predict optimal vent positions 3 hours ahead based on weather forecasts, reducing unnecessary fan activation by 18–22% annually. During summer nights, these systems prioritize passive cooling through open sidewalls, switching to mechanical ventilation only when dew point thresholds approach plant safety limits.

Smart and Automated Ventilation Technologies for Modern Large Greenhouses

Modern large greenhouse operations achieve unprecedented climate precision through intelligent ventilation systems combining sensor networks, automation, and predictive analytics. These technologies address the unique challenges of structures exceeding 10,000 sq ft, where traditional methods struggle with delayed responses and energy inefficiency.

Automated vent actuators and humidity-responsive smart sensors

Self-regulating vent systems now adjust openings within 30 seconds of detecting humidity threshold breaches. Precision sensors maintain 0.1°C temperature resolution across all growing zones, critical for delicate crops like hydroponic lettuce where 2°F fluctuations cause bolting.

IoT integration with fan and climate control systems

Centralized IoT platforms coordinate exhaust fans, circulation systems, and heating elements through a single dashboard. This proves vital in large greenhouses where operators previously wasted 18% of work hours manually checking peripheral bays, according to 2023 controlled environment agriculture data.

Emerging trends: AI-driven climate optimization in large greenhouse operations

Machine learning models now predict ventilation needs 12 hours ahead by analyzing hyperlocal weather patterns and canopy density changes. Early adopters report 60% fewer climate-related crop losses compared to timed ventilation systems, with AI optimization automatically compensating for solar gain in expansive glazed structures.

FAQ

What is the importance of ventilation in large greenhouses?

Ventilation is crucial in large greenhouses for regulating temperature, humidity, and CO₂ levels, which helps prevent plant diseases and promotes healthy growth.

How does greenhouse size affect ventilation needs?

Larger greenhouses require more air exchange rates and fan power to maintain proper airflow and temperature distribution, preventing heat and humidity build-up.

What are passive ventilation strategies for large greenhouses?

Passive strategies include using roof and side vents to utilize natural convection currents, alongside roll-up sidewalls and louvers for better air distribution.

How do active mechanical systems benefit large greenhouses?

Active systems like exhaust fans and circulation fans effectively manage heat stratification and humidity, especially in climates where passive methods alone are insufficient.

What is hybrid ventilation, and why is it beneficial?

Hybrid ventilation combines passive and active strategies for optimal climate control, balancing energy efficiency with precise management.

Table of Contents

- Understanding Ventilation Needs in a Large Greenhouse

- Passive Ventilation Strategies for Large Greenhouse Structures

- Active Mechanical Ventilation Systems in Large Greenhouses

- Hybrid Ventilation: Combining Passive and Active Methods for Optimal Control

- Smart and Automated Ventilation Technologies for Modern Large Greenhouses

- FAQ